OPTIMIZATION

OUR TECHNOLOGICAL FOCUS

The optimization of machine behavior, plant operations, and process control is a driving force for new developments and modernization. The optimization task is often multidimensional and requires consideration of many influencing factors. Our mechatronic system understanding and cross-domain experience open up a wide range of possible intervention points, which we know how to leverage effectively with our modeling and simulation expertise.

PARAMETER OPTIMIZATION

Our extensive experience and expertise in the field of multi-objective optimization (see especially the LCM software platform SyMSpace), automated parameter studies, parameter identification, and sensitivity analyses form a fundamental part of modeling and simulation projects.

PROCESS MODELS

Mathematical models enable the calculation of non-measurable process variables and the prediction of future process behaviors. Validated process models allow for the optimization of plant operations in simulation, without risk and without the time constraints that are always present in real-world testing.

CONTROL ENGINEERING

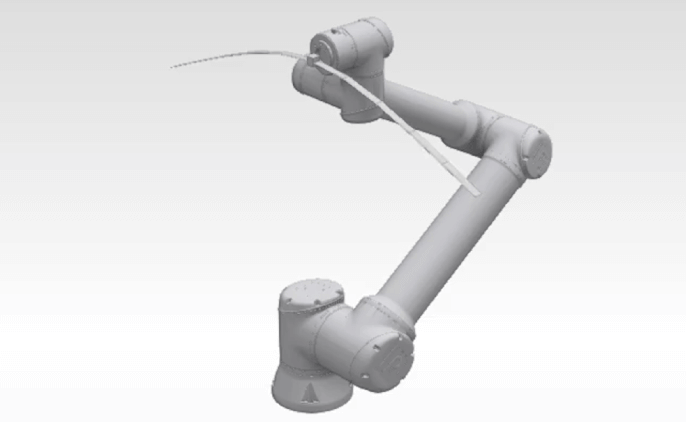

Effective control ensures rapid achievement of target values, ideally without overshooting and robust against external influences. Varying dynamics at different operating points and nonlinear behavior of actuators make this task challenging. With the right approaches and methods, significant performance advantages can be achieved.

OUR SERVICE OFFER

Knowledge transfer

We support you in establishing virtual commissioning in your company. This can be done by creating a show case for a trade fair, by validating a use case or by virtual commissioning of a customer project.

Development

We develop models and control engineering solutions for you.

In an application-oriented manner, we develop physics-based models of machines, plants or processes for simulation, virtual commissioning and digital twins. The use of suitable methods for model and parameter identification ensures a realistic representation of the real system behaviour by the model. Thus, the advantages of model-based feedforward and feedback control methods as well as the use of models for the estimation of process and state variables can be fully exploited.

Validation

Questions concerning stability and robustness can be systematically investigated by the availability of a suitable model. The examination of the concept for the sequence control of a complex plant and its behaviour in the event of a fault can be carried out within the framework of virtual commissioning without risk. In extensive investigations of a large number of test scenarios, the possibility of automated evaluations and analyses can save a great deal of time. For all these tasks, we are happy to make our know-how available to you.

Optimization

Maximum speed, minimum cycle times, best possible use of the control ranges, minimum energy consumption, reduced load on the system and actuators – with model-based optimization of process and control parameters, we determine the best performance for your system.

APPLICATIONS & BRANCH OF INDUSTRY

Reference Projects

For each of the above services we present here a reference project. See also the collection of projects projects at the top of the page.

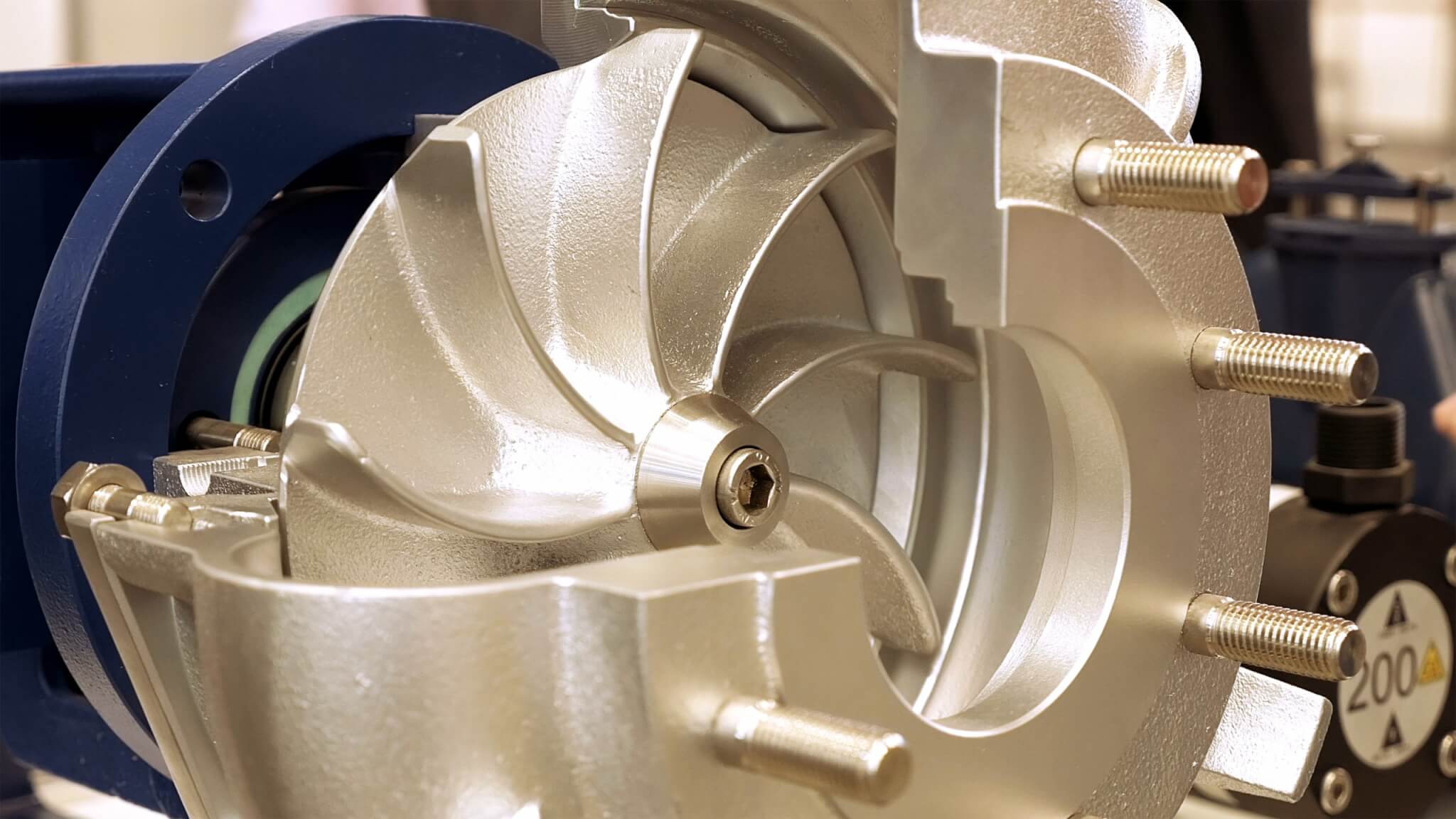

PROCESS MODELS – Turbomachines optimal development

The design and development of a customized turbomachine requires the interaction of several specialist domains. While a classic design approach is sufficient in simple cases, it quickly reaches its limits when it comes to more demanding requirements. For example, to achieve an optimized overall system, a holistic approach is recommended that optimizes all relevant sub-aspects while taking mutual dependencies into account:

- Fluid dynamics

- Electromagnetic drive

- Stability and rotor dynamics

- Thermal design and cooling

- Vibrations and acoustics

The SyMSpace development tool allows several of these areas to be optimized as a whole.

PROCESS MODELS – Cement Production

In a project with Cemtec, a model was developed for a grinding process consisting of a mill and a classifier. The identification of model parameters was carried out using plant and laboratory data. The process model allows for the estimation of material fineness through particle size distributions at various points in the process and provides insight into the dynamics of product changeovers. In the form of a Functional Mockup Unit (FMU), the model is also executable on the process computer and thus usable as a virtual sensor (soft sensor) in operation.

Goals, Motivation, Challenges

- Optimize steady state Operation (throughput, energy)

- Faster product change

- Increase product quality

Methods, Technology

- Model-based Estimation of particle size distribution

- Model Calibration with plant data and laboratory results

Solution, Benefits

- Increased System Knowhow

- Virtual Sensor

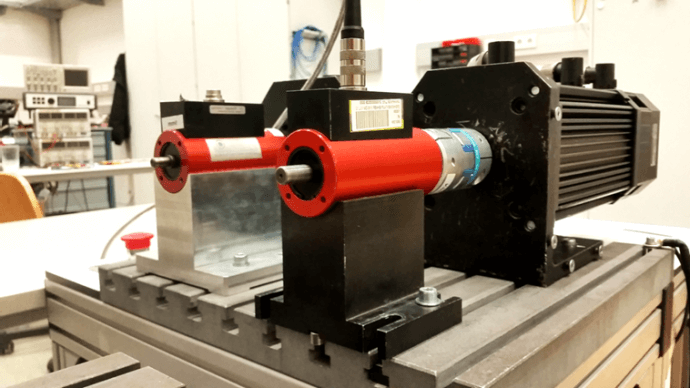

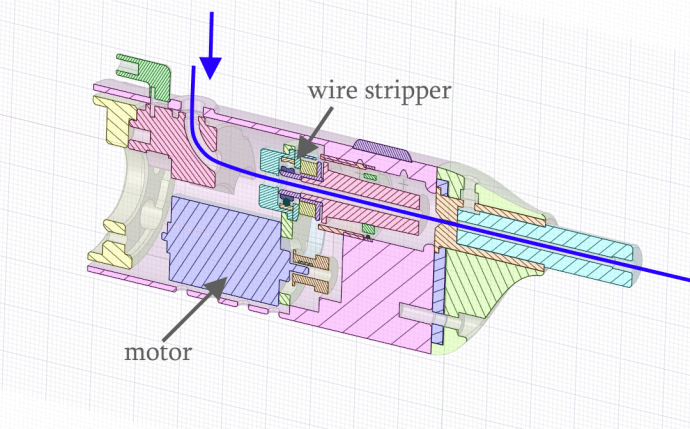

CONTROL ENGINEERING – Optimization of Setpoint Change

Achieving consistently optimal control quality with a variety of materials and different settings presents a significant challenge in the injection molding process. Additionally, the control system must be easy and reliable to parameterize during machine commissioning. This challenge was addressed and implemented in a project with Engel.

Goals, Challenges

- Reduce overshoot and rise time in pressure control

- Wide range of operation conditions

Methods, Technology

- Model-based control design

- Compensation of nonlinear effects

- Input Shaping for smooth setpoint change

- Pressure dependent control activation

Solution, Benefits

- Standard PID-control extended with compensation and input functions for increased performance

- Simulation studies reduce experimental testing

ADDITIONAL INFORMATION: LINKS & DOWNLOADS

- Modelling, simulation, control engineering: MATLAB/Simulink, SciLab/Xcos, Maple, MapleSim, Mathematica, HOTINT

- Virtual commissioning: Matlab/Simulink, Maple, IndustrialPhysics

- Automation systems: B&R AutomationStudio, Siemens TIA-Portal

- Automatic code-generation: Matlab Coder, MapleSim FMU Export, X2C

- Prototyping: LCM Electronic systems, dSpace, LabView

REFERENCE & REPORTS

Efficient testing with UFOs

(Semi-) autonomous vehicles present new challenges to the currently valid procedures for tests during development, but also to the test procedures for approval. In order to prove the safety of the many (partially) autonomous systems that interfere with the driving...

REVIEW: THAT WAS 4SMARTS 2019

The focus of the symposium 4SMARTS from 22nd to 23rd May 2019 was the interdisciplinary field of active, intelligent and adaptive - in short: smart - structures and systems. With numerous contributions from research and application, the symposium covers all relevant...

Touchscreen with haptic feedback | Innovation Award 2013

The Linz Center of Mechatronics GmbH has developed a novel touch screen with haptic feedback. The core is a transparent plate, which is actively deformed by piezoelectric materials and thus provides the operator with haptic feedback. The invention was awarded the...